Biofloc fish farming is revolutionizing aquaculture in India, offering farmers a sustainable and profitable way to produce fish with minimal water usage and maximum efficiency. This comprehensive guide will walk you through everything you need to know about starting your biofloc fish farming journey, from understanding the technology to setting up your first system.

What is Biofloc Fish Farming Technology?

Biofloc technology (BFT) is an innovative aquaculture system that maintains water quality through beneficial microbial communities. Unlike traditional fish farming methods, biofloc systems create a balanced ecosystem where beneficial bacteria convert fish waste into protein-rich feed, reducing the need for water changes and external feed supplements.

The biofloc system works by maintaining a carbon-nitrogen ratio that promotes the growth of beneficial microorganisms, which form flocs – clusters of bacteria, algae, and organic matter that fish can consume as natural food.

Key Benefits of Biofloc Fish Farming in India

Water Conservation Benefits

- 90% less water usage compared to traditional fish farming methods

- Zero water discharge system – perfect for water-scarce regions in India

- Continuous water recycling through biological filtration

Economic Advantages

- Higher fish density: 3-5 kg fish per cubic meter compared to 0.5-1 kg in traditional ponds

- Reduced feed costs by 20-30% due to natural protein production

- Faster growth rates: Fish reach market size 25% quicker

- Year-round production with controlled environment systems

Environmental Benefits

- Sustainable aquaculture with minimal environmental impact

- Reduced antibiotic usage due to improved fish health

- Carbon footprint reduction through efficient resource utilization

Production Benefits

- Disease resistance: Healthier fish with stronger immune systems

- Better feed conversion ratio (FCR) of 1:1.2 compared to 1:1.8 in traditional systems

- Consistent production regardless of seasonal variations

Essential Components for Biofloc Fish Farming Setup

Tank Requirements

- Circular or rectangular tanks made of HDPE, concrete, or tarpaulin

- Tank size: 1,000-10,000 liters for beginners, scalable to commercial sizes

- Depth: 1.2-1.5 meters for optimal fish movement and aeration

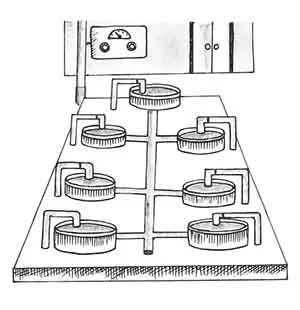

Aeration System

- Continuous aeration is critical – minimum 5-8 watts per cubic meter

- Air blowers and diffuser stones for uniform oxygen distribution

- Backup power supply to prevent fish mortality during power cuts

Water Quality Monitoring Equipment

- pH meter: Maintain pH between 7.0-8.5

- Dissolved oxygen meter: Keep DO levels above 4 ppm

- Temperature monitoring: Optimal range 26-30°C for most fish species

- Ammonia and nitrite test kits for water quality management

Biofloc Formation Materials

- Carbon sources: Molasses, wheat flour, or rice bran for C:N ratio maintenance

- Probiotics: Beneficial bacteria cultures for system establishment

- Minerals: Calcium carbonate and magnesium for water hardness

Step-by-Step Biofloc Setup Process

Phase 1: System Preparation (Week 1-2)

Tank Installation

- Site selection: Choose level ground with electricity and water access

- Tank placement: Ensure proper drainage and accessibility for maintenance

- Plumbing setup: Install inlet/outlet pipes and drainage systems

Equipment Installation

- Aeration system: Install air blowers and connect airline networks

- Monitoring equipment: Set up pH meters and oxygen monitoring systems

- Backup systems: Install generators or battery backup for aeration

Phase 2: Biofloc Development (Week 3-4)

Water Preparation

- Fill tanks with freshwater – dechlorinate if using municipal water

- Add probiotics: Introduce beneficial bacteria at 2-3 ppm concentration

- Carbon source addition: Mix molasses at 10-15 ppm daily

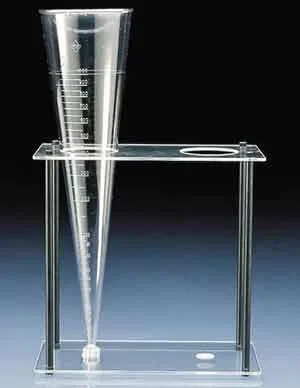

Floc Formation Monitoring

- Daily water testing: Monitor ammonia, nitrite, and pH levels

- Visual inspection: Watch for brownish-green floc formation

- Adjust carbon dosing based on nitrogen levels

Phase 3: Fish Stocking (Week 5)

Species Selection for Beginners

- Tilapia: Hardy, fast-growing, ideal for beginners

- Catfish (Magur): High market demand, suitable for Indian conditions

- Rohu: Popular freshwater fish with good biofloc adaptation

Stocking Procedures

- Stocking density: 100-200 fingerlings per cubic meter for beginners

- Acclimatization: Gradually introduce fish to biofloc water

- Initial feeding: Start with 3-5% body weight feeding rate

Daily Management and Maintenance

Water Quality Management

- Morning checks: Monitor pH, dissolved oxygen, and temperature

- Floc volume measurement: Maintain 15-20 ml/L settled volume

- Carbon source addition: Add molasses based on nitrogen levels

Feeding Management

- Feed quality: Use high-protein (28-32%) commercial fish feed

- Feeding frequency: 3-4 times daily for optimal growth

- Feed adjustment: Reduce feeding if floc volume increases excessively

System Monitoring

- Aeration check: Ensure continuous operation of air blowers

- Fish behavior observation: Watch for stress indicators or disease signs

- Equipment maintenance: Regular cleaning of diffusers and filters

Investment and Returns Analysis

Initial Investment Breakdown

- Small-scale setup (5,000L): ₹1.5-2.5 lakhs including equipment

- Medium-scale setup (20,000L): ₹5-8 lakhs for complete system

- Commercial setup (1,00,000L+): ₹25-40 lakhs depending on automation

Operating Costs (Monthly)

- Electricity: ₹3,000-5,000 for aeration and monitoring

- Feed costs: ₹15,000-25,000 depending on production scale

- Maintenance: ₹2,000-3,000 for consumables and repairs

Revenue Potential

- Production capacity: 3-5 kg/cubic meter every 4-6 months

- Market price: ₹200-400 per kg depending on fish species

- Break-even period: 12-18 months for well-managed systems

Common Challenges and Solutions

Water Quality Issues

Problem: High ammonia or nitrite levels

Solution: Increase aeration, add carbon source, reduce feeding temporarily

Floc Imbalance

Problem: Too much or too little floc formation

Solution: Adjust carbon:nitrogen ratio, monitor feeding rates

Disease Management

Problem: Fish mortality or stress

Solution: Maintain optimal water parameters, use probiotics, consult experts

Success Tips for Biofloc Fish Farming

Technical Best Practices

- Start small: Begin with 2,000-5,000L tanks to gain experience

- Maintain records: Track water parameters, feeding, and growth daily

- Regular training: Attend biofloc workshops and training programs

Business Management

- Market research: Identify local demand and pricing before starting

- Quality control: Maintain consistent fish quality for better market rates

- Scaling strategy: Gradually expand based on initial success

Getting Professional Support

Starting a biofloc fish farming venture requires proper guidance and technical expertise. Many farmers benefit from professional consultancy services that provide:

- Site assessment and system design recommendations

- Hands-on training for biofloc management techniques

- Ongoing technical support for troubleshooting and optimization

- Business planning assistance for scaling and profitability

Ready to Start Your Biofloc Journey?

Biofloc fish farming represents the future of sustainable aquaculture in India. With proper setup, management, and guidance, it offers an excellent opportunity for profitable fish production while conserving water and protecting the environment.

Whether you’re a traditional farmer looking to diversify or an entrepreneur seeking a profitable venture, biofloc technology provides a proven path to success in Indian aquaculture.

For personalized guidance on setting up your biofloc fish farming system, including site evaluation, system design, and training programs, contact our experienced consultancy team to ensure your venture starts on the right path to profitability.